Peroxide Crosslinked Semiconductive Internal Shielding Material (35KV) for Conductor of XLPE Insulated Cable

Product name, model, use

| Product model |

Product Name |

Features and uses |

|---|---|---|

|

PYJD |

Peroxide Crosslinked Semiconductive Shielding Material for Conductor of XLPE Insulated Cable |

Crosslinked Semiconductive Internal Shielding Material 35 KV and Below |

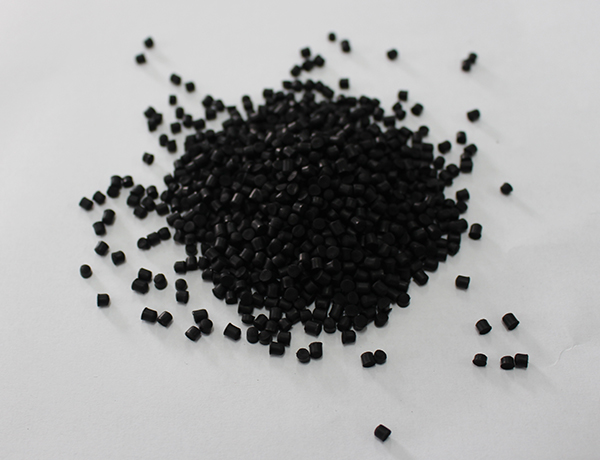

Product introduction

This project is a semi-conductive shielding material obtained by mixing, plasticizing and extruding granules with polyolefin as the base material, conductive carbon black and various specific additives.

Product Features

·Excellent Conductivity ·Excellent anti-aging properties

·Excellent processability ·Excellent peelability

· excellent mechanical properties

Usage features

Cross-linked semi-conductive shielding materials are suitable for cable conductors and allow a maximum operating temperature of 90 ° C for long periods of time.

Thermoplastic semi-conductive shielding materials are suitable for cable conductors and allow a maximum operating temperature of 70 ° C for long periods of time.

Processing Guide

It is suitable for processing on the existing screw equipment of power cable, and can obtain good extrusion process effect.

Recommended processing temperature:

| Zone | 1# | 2# | 3# | 4# | 5# | Head |

|---|---|---|---|---|---|---|

| Temp(℃) | 80 | 85 | 90 | 95 | 100 | 110 |

Storage and packaging

The semi-conductive shielding material should be stored in a clean, dry and ventilated warehouse. The storage temperature should not be lower than 0 °C, and the stacking height should not exceed three boxes. The storage period shall not exceed six months from the third day of production.

The semi-conductive shielding material should be packaged in moisture-proof packaging. The inner bag is made of PE composite film bag. After being sealed and packaged, it is packed into a hard corrugated cardboard box which is not easy to be damaged. The waterproof film of the outer casing is 500Kg± 1Kg per box.

Technical Features

| Physical performance |

Unit |

Standard value |

SH8505 or DTI-36 |

Standard value |

SH8506 or DTO-36-N |

Test method |

|---|---|---|---|---|---|---|

|

density |

g/cm3 |

≤1.18 |

1.12 |

≤1.18 |

1.15 |

GB/T 1033.1 |

|

Low temperature impact embrittlement temperature |

℃ |

-40 |

pass |

-40 |

pass |

GB/T 5470 |

|

Heat extension,200℃0.2MPa |

|

|

|

|

|

GB/T 2951.5 |

|

Elongation under load |

% |

≤100 |

50 |

≤110 |

48 |

|

|

Permanent deformation after cooling |

% |

≤15 |

0 |

≤15 |

0 |

|

|

Melt Index 100℃21.6Kg |

g/10min |

≤1.5 |

1 |

≥2.0 |

1.5 |

GB/T 3682 |

|

|

|

|

|

|

|

|

|

Mechanical properties |

Unit |

Standard value |

SH8505 or DTI-36 |

Standard value |

SH8506 or DTO-36-N |

Test method |

|

Tensile Strength |

MPa |

≥12 |

14 |

≥10 |

14.2 |

GB/T 1040.3 |

|

Elongation at break |

% |

≥180 |

240 |

≥200 |

290 |

GB/T 1040.3 |

|

|

|

|

|

|

|

|

|

Aging performance |

Unit |

Standard value |

SH8505 or DTI-36 |

Standard value |

SH8506 or DTO-36-N |

Test method |

|

Heat aging performance 135℃×168h |

|

|

|

|

|

GB/T 2951.12 |

|

Tensile strength change rate |

% |

±30 |

1 |

±30 |

15 |

GB/T 1040.3 |

|

Rate of change in elongation at break |

% |

±30 |

-27 |

±30 |

-22 |

GB/T 1040.3 |

|

|

|

|

|

|

|

|

|

Electrical performance |

Unit |

Standard value |

SH8505 or DTI-36 |

Standard value |

SH8506 or DTO-36-N |

Test method |

|

20℃ Volume resistivity |

Ω·cm |

≤100 |

31 |

≤100 |

90 |

GB/T 1410 |

|

90℃ Volume resistivity |

Ω·cm |

≤5000 |

491 |

≤2500 |

680 |

GB/T 1410 |

|

Volume resistance after heat aging 100℃×168h |

h |

|

|

|

|

|

|

90℃ Volume resistivity |

Ω·cm |

≤1000 |

306 |

≤1000 |

489 |

GB/T 1410 |

|

|

|

|

|

|

|

|

|

Peel strength |

N/cm |

- |

- |

10-40 |

29 |

|

|

Peel strength after aging 100℃×168h |

h |

|

|

|

|

|

|

Peel strength |

N/cm |

- |

- |

10-45 |

29 |

|